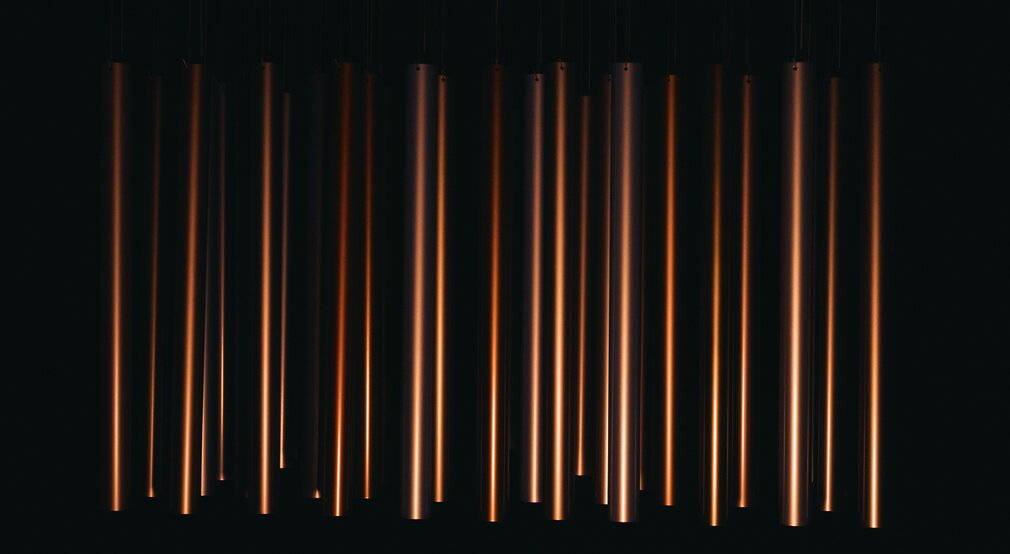

Melted Metal – Metallic Allure with timeless Elegance

Melted Metal effect powder coatings are the latest innovation from IGP Powder Coatings. They deliver a sophisticated reproduction of the look of metals, opening up new options for façades and design objects. These powder coatings give any object a brilliant metal sheen for a stunning appearance.

Innovation for timeless aesthetics

IGP effect coatings are based on the proven, super durable basecoat IGP-HWFclassic, Series 59. They offer long-lasting color and chalking resistance and meet the highest standards in accordance with Qualicoat (Class 2) and AAMA 2604. The patented metal interference pigment system delivers a nuanced reproduction of the shade and metallic sheen of precious coin metals and their alloys. These alloys are composed of the elements gold, copper, and silver. Yet no (semi-)precious metals are needed to create the premium surfaces. Moreover, convincing representations of chromium steel, polished aluminum, and elegant shades from the anodized color range can also be achieved. Melted Metal premium coatings offer exceptional characteristics. Thanks to their technical properties, they enable new levels of color saturation, covering capacity, and color space in applications on façades and design objects.

Robust surfaces, fewer scratches

The enhanced scratch resistance of these powder coatings offers a number of benefits in application. Because the coated surfaces are less susceptible to scratching, they are easier to handle during transportation and installation. Another benefit is that the surfaces are better protected against gloss damage caused by cleaning. During both intensive and maintenance cleaning, the improved scratch resistance of the powder coatings ensures greater durability and protects the aesthetic value of the coated object. These powder coatings are available as smooth surface coatings in matte and silk gloss versions.

Resource-efficient thin-film technology

Melted Metal powder coatings are based on UTP (ultra-thin pigment) technology. Due to the minimized particle thickness and high optical effectiveness, UTP technology significantly contributes to optimized resource utilization. The thin-film effect particles, perfectly reproducible in size and thickness ratio, are coated and stabilized with silicon silicate. This prevents tarnishing of the metal substrates from oxidation and ensures optimal moisture resistance and weather stability.

Green Building Label

Melted Metal premium coatings meet the criteria for various Green Building labels. Energy-efficient curing of the varnish at temperatures from 170°C, as well as the absence of solvents (VOC) and the use of formaldehyde-free formulas, make these powder coatings an environmentally friendly option for sustainable building designs. The product group comes with an environmental product declaration certified by the Institut für Bauen und Umwelt e.V. (EPD-IGP-20220255-IAC1-DE). Go to meltedmetal.igp-powder.com for fresh inspiration and more information.