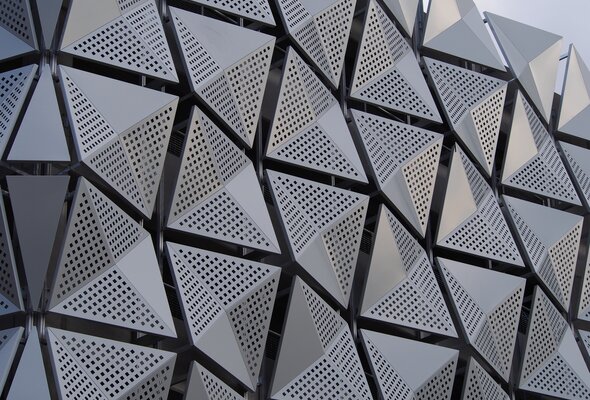

The Supporting Power of your Architecture

High-performance Coating Solutions.

The polyester coatings specially developed by IGP offer reliable protection and durability for your steel construction projects, both in interior and exterior environments. With our low-temperature powder coatings, you can optimize process speeds and save valuable time. They also cut energy costs. Choose IGP

powder coatings for lasting, reliable protection of your heavy steel constructions.

Coating Solution for Heavy Steel Constructions

Extended Resistance – Longer Service Life.

IGP powder coatings for heavy steel constructions stand out for their high reactivity. This ensures the curing temperatures are achieved faster, even for large and solid steel components.

Low-temperature polyester powder coatings are state-ofthe-art solutions for both interior and exterior applications. Their wide curing window massively reduces the risks of overand under-curing. One fundamental advantage of powder coatings over liquid coatings is that they contain almost no volatile organic compounds (VOC-free), which is better for the environment.

Weather-resistant and long-lasting

All products in the IGP-DURA®one range are weather-resistant and ideal both for interior and exterior applications. Using a suitable primer can significantly improve the corrosion protection even further. This not only extends the service life of the coated steel components, but also preserves the value of the entire object over a long time period.

Powder Coatings for Top Protection of Steel Surfaces

Powder Coating for Sustainable and Long-lasting Protection.

The IGP-DURA®one 56 and 66 powder coating series set new benchmarks in energy efficiency and surface quality – with low curing temperatures, high stability, and a broad range of colors. IGP-KORROPRIMER 18 combines perfectly with our topcoats for corrosion protection of steel wherever it is necessary.

IGP-DURA®one

IGP-DURA®one 56 is the most energy-efficient qualitycertified powder coating series on the market. It impresses not only thanks to low minimum curing temperatures (15 min. / 160°C), but also due to its high application efficiency and excellent over-curing and gloss stability. In addition to QUALICOAT and GSB quality certification, the IGP-DURA®one 56 series also comes with an environmental product declaration (EPD). These documents provide valuable information for sustainability assessments and about their contribution to environmental protection.

IGP-DURA®one 66 achieves cross-linking from a minimum curing temperature of 150°C, further enhancing our product range with additional surface options. Both series are available in a wide range as products in stock. Customers can order sample panels, and custom color matches are also possible.

IGP-KORROPRIMER

IGP-KORROPRIMER 18 provides long-lasting corrosion protection for steel constructions in the construction industry. Its high resistance ensures lasting material inte-grity for maximum protection and durability.

Certification, Training and Quality Assurance

For Top Performance and Resistance.

IGP offers customized certification programs and services for maximum process reliability.

Practical training for outstanding coating quality

The IGP training program gives coaters at all levels of experience the know-how they need to achieve process reliability with powder coatings. DIN-certified IGP coating inspectors provide practical training and on-site consultations. They also issue professional certifications of corrosion protection measures.

- Advanced Training – deeper knowledge of powder coating technology, quality assurance, and troubleshooting.

- Professional Training – extended expertise, error prevention, process optimization.

- Individual Training – customized training courses under real-life conditions on your own machines

Optimization and quality assurance

IGP optimizes your production process with expertise in powder coatings and coating processes. Weathering and corrosion testing can provide evidence of how durable the coated objects are. We offer fast technical support and an extensive service in this area.

IGP certification programs

IGP’s tailor-made certification programs guarantee top quality standards and optimized processes. The IGP Certified Coater Program (CCP) for coating companies ensures a uniform understanding of processes and consistent, high-quality powder coating results. Certification boosts your market reputation, improves your

production processes, and guarantees compliance with demanding quality requirements.

The program ensures process reliability and uniform standards for coaters and powder coating manufacturers. The IGP Certified Coater Program consists of two levels:

- Level 1 – IGP Basic

Optimization of your processes (storage, application, distribution) with subsequent certification as an Approved Applicator of IGP Powder Coating Systems. - Level 2 – IGP Coating Partner

Building on product certification, IGP awards product certificates for challenging coating types.