TI112 – IGP-Living Surfaces®

Introduction

Due to the coarsely ground nature of some powder coatings in the IGP-Living Surfaces®series (Group D), special requirements are placed on the system technology (see VR213).

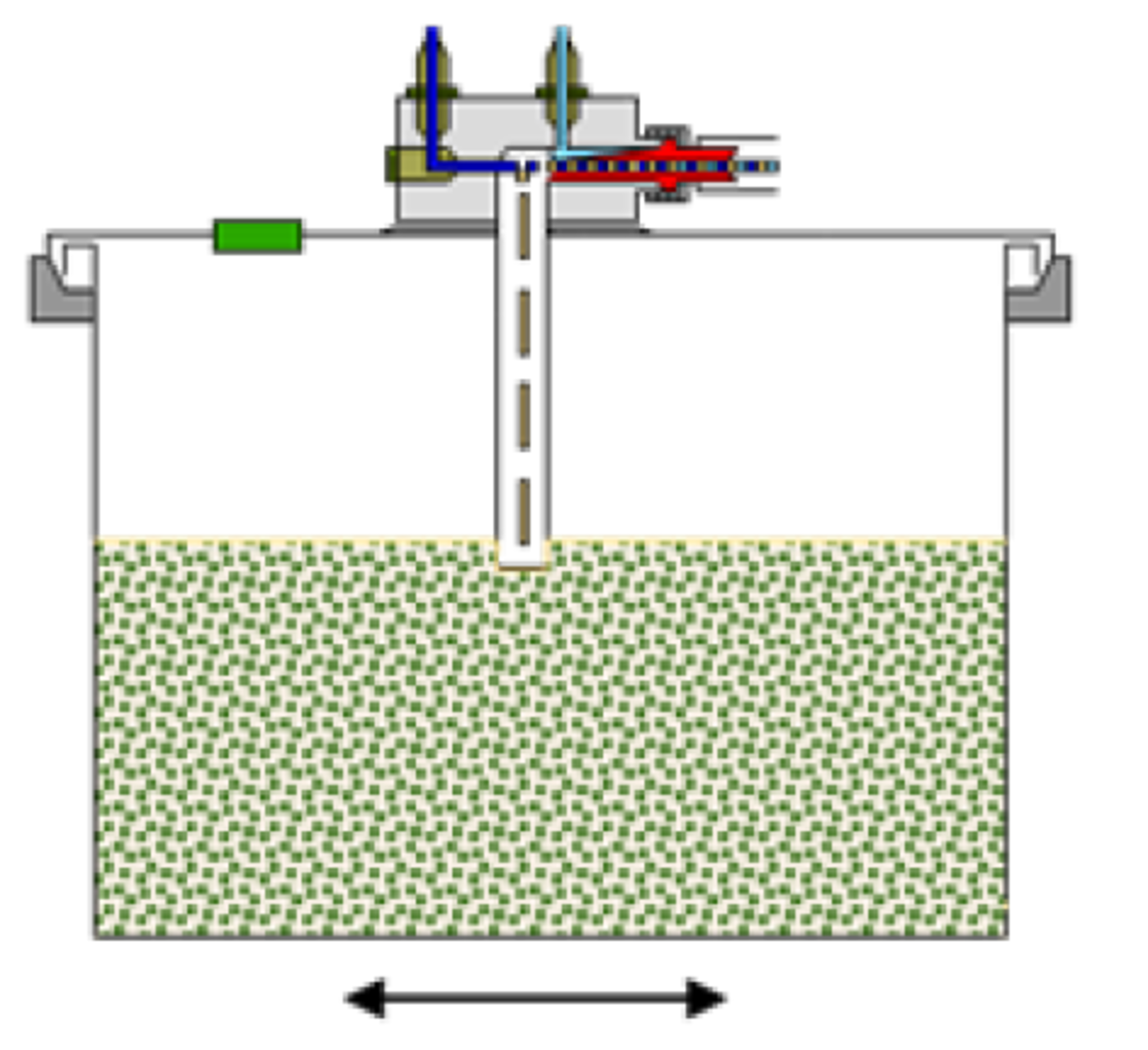

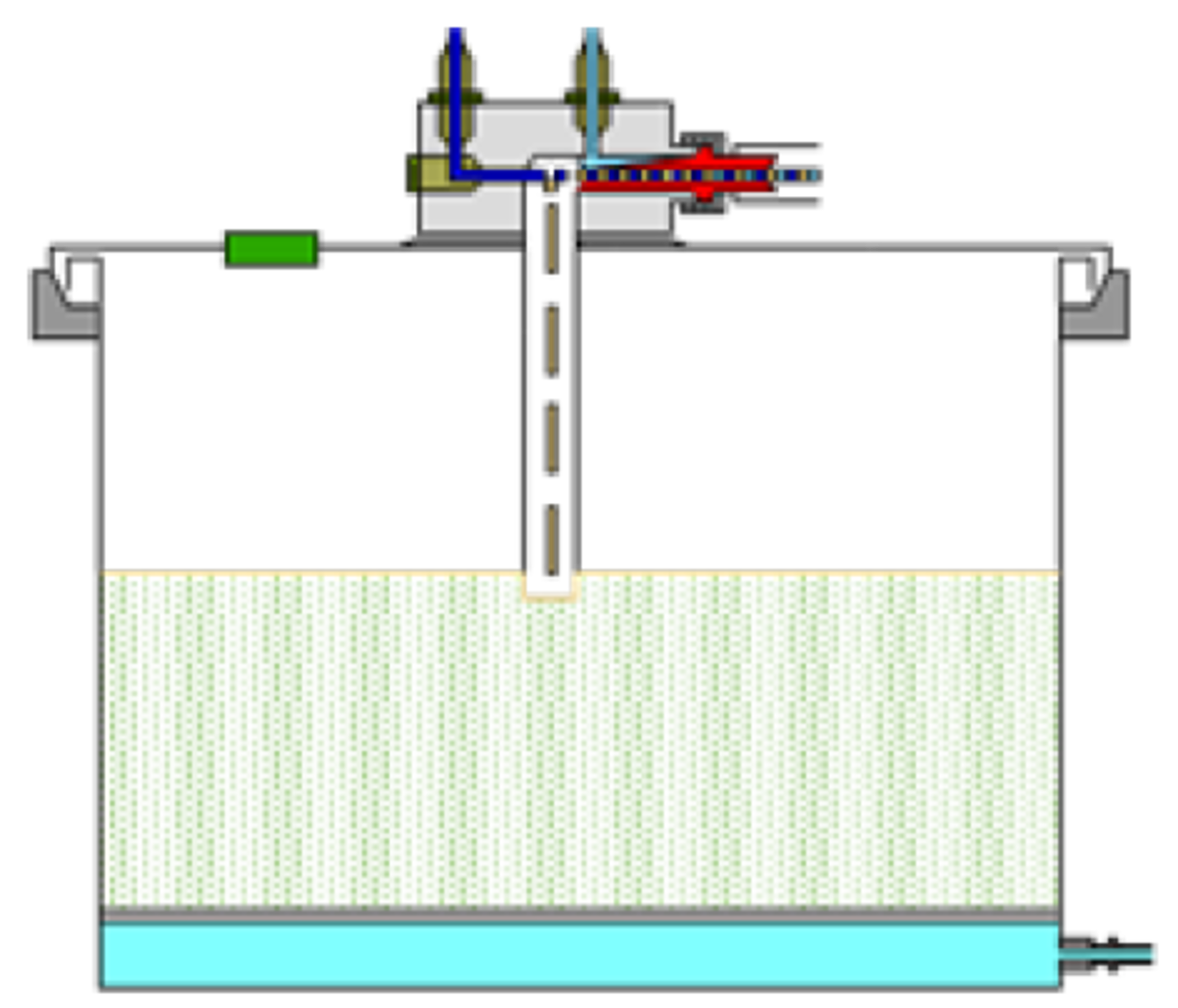

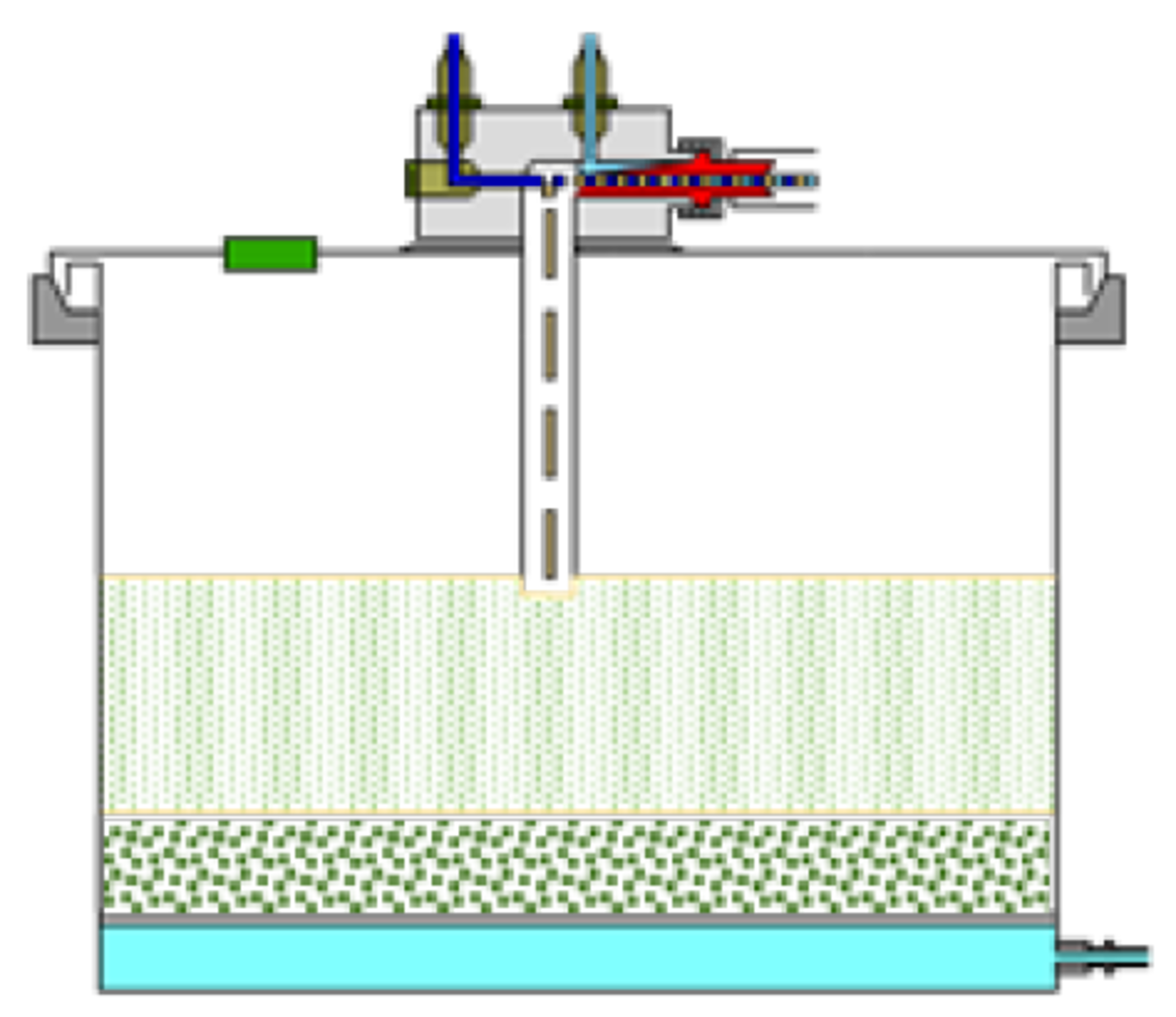

Depiction of segregation during compressed air fluidisation

Normal powder coating with fluidisation

Due to the uniform particle distribution of the powder coating, all powder particles receive a uniform buoyancy and can therefore be kept in suspension.

Coarse grinding with fluidisation

Due to the very large differences in Particle size, the finer parts of the powder coating are suspended. However, the coarser and therefore significantly heavier parts cannot be suspended and concentrate at the bottom of the powder container immediately after fluidising air is added.

There, the coarser parts are sucked out first, which means that after a short coating time, only the finer part remains in the container and the desired surface characteristics can no longer be achieved.

Coarse grinding with vibration

Due to the low physical impact on the powder coating, there is almost no segregation of the individual coating components. This means that a uniform surface can be achieved over the entire coating period. Vibration is only required to ensure that the powder trickles down the suction tube.