The initial situation

The planned introduction of the new IGP-DURA®one 56 low-temperature powder coating system as a replacement for the IGP-DURA®face 58 product series has prompted Schmid to consider an early changeover of its own coating operations. Various oven graphs were tested in a cycled conveyor oven, including trials without adjusting the oven parameters. All test results were evaluated in accordance with the Qualicoat standards in the company’s own laboratory. The results indicate that no major problems can be expected from a changeover.

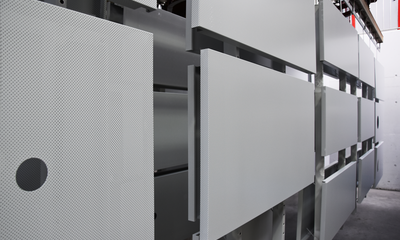

The solution

The first step was to successfully reduce the oven temperature by 10°C. Despite the fact that various product carriers with different powder coatings pass through the oven, and the throughput speed needs to be adjusted due to the lower oven temperature, IGP-DURA®one 56 exhibits optimal coating performance. Its over-curing and gloss stability with surface aspects such as matte, silk gloss, and fine structure remains at the highest level. IGP-DURA®one 56 achieves full compliance with all Qualicoat standards.

The added value

For Schmid GmbH, the benefits of IGP-DURA®one 56 are clear. Permanently reducing the oven temperature by 10°C leads to immediate savings in energy costs. Thanks to the high over-curing stability of IGP-DURA®one, materials of varying thicknesses can be coated without any problems. The gloss stability of the low-temperature powder coatings is impressive, and the short delivery times and wide range of available colors (RAL, NCS) in the surface aspects matte, silk gloss, and fine structure ensure optimized response times for customers.